application of brinell hardness test|brinell hardness test chart : manufacturing Brinell Hardness Test: This test measures the diameter of an indentation made on the surface of the material by a hard steel ball under a specific load. . Applications of Hardness Testing. Hardness testing is an . 14 de jan. de 2022 · Vikings. Two androids are tasked with raising human children on a mysterious virgin planet; as the human colony threatens to be torn apart by religious .

{plog:ftitle_list}

webO resultado da Look Loterias das 23 horas de hoje é informado nessa página logo após o sorteio, confira os sorteios das 23 hs de hoje da Look Loterias de Goiás. Acesse o site Meu Jogo do Bicho diariamente e confira o resultado do jogo do bicho de Goiás que é conhecido como Look Loterias. Participe do nosso grupo de WhatsApp e receba o .

Application of Brinell Hardness Test in Various Industries. The Brinell Hardness Test finds extensive application across diverse industries, playing a crucial role in assessing material hardness and ensuring the quality and .

Brinell Hardness Test: This test measures the diameter of an indentation made on the surface of the material by a hard steel ball under a specific load. . Applications of Hardness Testing. Hardness testing is an .Time-consuming: The Brinell hardness test typically requires a longer duration of load application than other hardness testing methods. This can make it a time-consuming process. Requires a larger sample size: The spherical .

ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness tests. ISO 6506: This standard mirrors ASTM E10, as it contains the standard method for measuring the Brinell hardness of metals. ISO 6507: This standard contains the details for the Vickers hardness test in metallic materials. Selecting the Best Hardness Testing Method for Your Application. The following table provides an overview of various materials, including metals, along with the corresponding hardness testing methods applicable to each. . Brinell Hardness Test. The Brinell hardness test is ideal for measuring the hardness of metals with coarse or .

The application of hardness testing enables you to evaluate a material’s properties, such as strength, ductility and wear resistance, and so helps you determine whether a material or material treatment is suitable for the purpose you require. . The Brinell hardness test (HBW) indentation leaves a relatively large impression, using a . Online Article: “Hardness Testing: A Comprehensive Guide” – Buehler. Source: Buehler; Summary/Annotation: This article from Buehler provides an in-depth overview of hardness testing, discussing different methods such as Rockwell, Vickers, Brinell, and Knoop hardness tests. It explains the principles behind each method, the types of . General Information about the Brinell Hardness Test. The Brinell hardness test involves pressing a hard ball indenter, usually made of tungsten carbide, into the material’s surface with a specified force. The diameter of the ball is typically 10 mm, but smaller diameters such as 2.5 mm can also be used for specific applications. Hardness testing is a vital process in many industries. Our guide explains everything you need to know about this crucial technique. . Characteristics and Application of Brinell Hardness. This method is well-suited for coarse or heterogeneous materials due to its large indentation area and high measurement accuracy. However, due to the large .

Andrew Fee, Selection and Industrial Applications of Hardness Tests, Mechanical Testing and Evaluation, Vol 8, ASM Handbook, Edited By Howard Kuhn, Dana Medlin, ASM International, 2000, . Brinell hardness test. Rockwell hardness test. Vickers hardness test. Knoop hardness test. surface condition. hardness. accuracy. calibration. case depth .

SCOPE. The Brinell hardness test is an empirical indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, and other physical characteristics of metallic materials, and may be useful in quality control and selection of materials.Application of Brinell Hardness Test in Various Industries. The Brinell Hardness Test finds extensive application across diverse industries, playing a crucial role in assessing material hardness and ensuring the quality and reliability of products. Below are some key industries where the Brinell Hardness Test is commonly employed. 1. ManufacturingBrinell Hardness Testing: Involves applying a known load to the surface of the test sample via a hardened steel or . tensile strength, yield strength, and ductility, contributing to the manufacturing success. With an immense range of applications, hardness testing forms the backbone of several industries such as automotive, aerospace, and .

Direct Measurement: In certain applications, the material’s hardness stands as a crucial and directly measurable characteristic, eliminating the need for inference from physical properties. . Brinell Hardness Test: Using a spherical indenter, this test determines the hardness by measuring the diameter of the indentation created by a known .

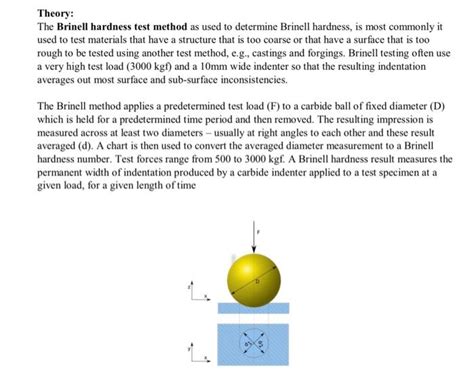

The Right Hardness Testing Method for Your Metals Application The right hardness test method depends on the material being tested and the specific requirements of the application. Understanding the differences . Brinell hardness testing methods are defined in the following standards: ASTM E10 and ISO 6506. . Lower forces and smaller diameter balls are also used in specific applications. Similar to Knoop and Vickers testing, . Hardness testers are complex in design but simple in principle, operation and application. They measure the hardness of a material as its ability to resist permanent deformation from an applied force. . Brinell hardness .Brinell Hardness Testing. The Brinell hardness test method as used to determine Brinell hardness is defined in ASTM E10. Most commonly it is used to test materials that have a structure that is too coarse or that have a surface that is too rough to be tested using another test method, e.g., castings and forgings.

Conducting a hardness test using the Rockwell hardness method can be difficult, especially if you misunderstand its principles and application. Not to overstate it, but without an understanding of the Rockwell hardness method, you might end up going round in circles or, worse still, end up with an inaccurate material hardness value. Rockwell hardness testing, Brinell hardness testing, and microhardness testing are all methods used to verify heat treatment results. Capabilities. Processes. Heat Treating. Annealing; . The downward distance the indenter traveled from the application of the light load to the release of the heavy load is recorded and used to calculate hardness.For metric applications the tensile strength in N/mm 2 can be obtained by multiplying the Brinell number by 3.54 for annealed steels, . In the Brinell test, hardness is defined as load divided by the curved area of the indentation; in the Vickers test, the diagonal of the square impression is measured. The Vickers test was in due course .

moisture meter 19 percent

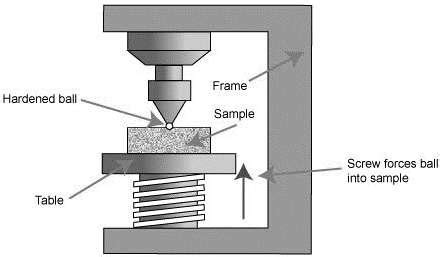

In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test methods.. The deeper a defined indenter penetrates the surface of a specimen with a specified test load, the softer the material that is being tested. Among the various hardness testing methods, the Brinell and Rockwell tests are two of the most commonly used techniques. In this article, we will compare these two methods, highlighting their differences and applications. Brinell Hardness Test. The Brinell hardness test is named after its inventor, Johan August Brinell. It measures the hardness .The Brinell hardness test consists of applying a constant load or force, usually between 187.5 and 3000Kgf, for a specified time (from 10 – 30 seconds) typically using a 2.5 or 10mm diameter tungsten carbide ball (see schematic in the image to your right – Figure 23.3). . Applications. Brinell hardness testing is typically used in testing .Brinell hardness test has wide applications in the metal forging and manufacturing circles, where it is used for ascertaining the tensile strength of metals. Since the range of applied force ranges from low to high, the Brinell hardness test can be applied to metals like copper and aluminum using low forces and cast irons and steel with higher .

2. Brinell Hardness Test. The Brinell test uses a larger spherical indenter, usually made of steel or carbide, and applies a heavy load to the material. The diameter of the indentation is measured to calculate the Brinell hardness number (HB). This method is ideal for testing softer or larger materials like cast iron and steel.The Brinell scale characterizes the indentation hardness of materials through the scale of penetration of an indenter, loaded on a material test-piece. It is one of several definitions of hardness in materials science. The typical brinell hardness test uses a 10 millimeters (0.39 in) diameter steel ball as an indenter with a 3,000 kgf (29 kN .

brinell hardness tester diagram

Adult. Statistics. Favorites. Posts filter. 🔞🔥ᐯᗩᏃᗩᗞᝪᔑ ᗞᗩᔑ ᑎᝪᐯᏆᑎᕼᗩᔑ +18 🔞🔥. 22 Feb, 12:00. Novinha de óculos se exibindo no quarto vaza 🔥. COMPLETO NO VIP⭐️. ⭐️Faça parte do maior vip de vazados , novinhas , .

application of brinell hardness test|brinell hardness test chart